The polyurethane foam industry pumps many different liquids – they may be corrosive, non-lubricating or viscous and may contain suspended solids. Pumping is often done on high-speed production lines, so reliability and consistency are very important. Seal-less design makes the Hydra-Cell® an ideal pump for these applications.

In metering and dosing operations the Hydra-Cell has a distinct size advantage over traditional metering pumps, being very much more compact. Not only does it take up less space, it also offers substantial savings on the total costs of pump ownership and operation – including acquisition costs, energy usage and expenditure on maintenance and repair.

Flow is virtually pulse-less, frequently eliminating the cost of pulsation dampeners.

Additives of many types are often injected as part of the process. Many of these chemicals are corrosive and react with moisture or air to form micron crystals which can be very abrasive e.g. Isocyanates. Hydra-Cell pumps seal-less design and unique check valve design means these types of chemicals can be pumped reliably in high speed production lines.

Environmental legislation has forced the move to blowing agents such as Pentane. No leaks can be tolerated in pumping this non-lubricating, highly volatile, flammable and toxic liquid – but the Hydra-Cell’s seal-less design enables the pump to handle Pentane reliably, without difficulty.

Increased use of filled Polyols means that the injection pumps must be able to pump liquids with suspended solids. Hydra-Cell's seal-less design eliminates seal maintenance when pumping these types of Polyol.

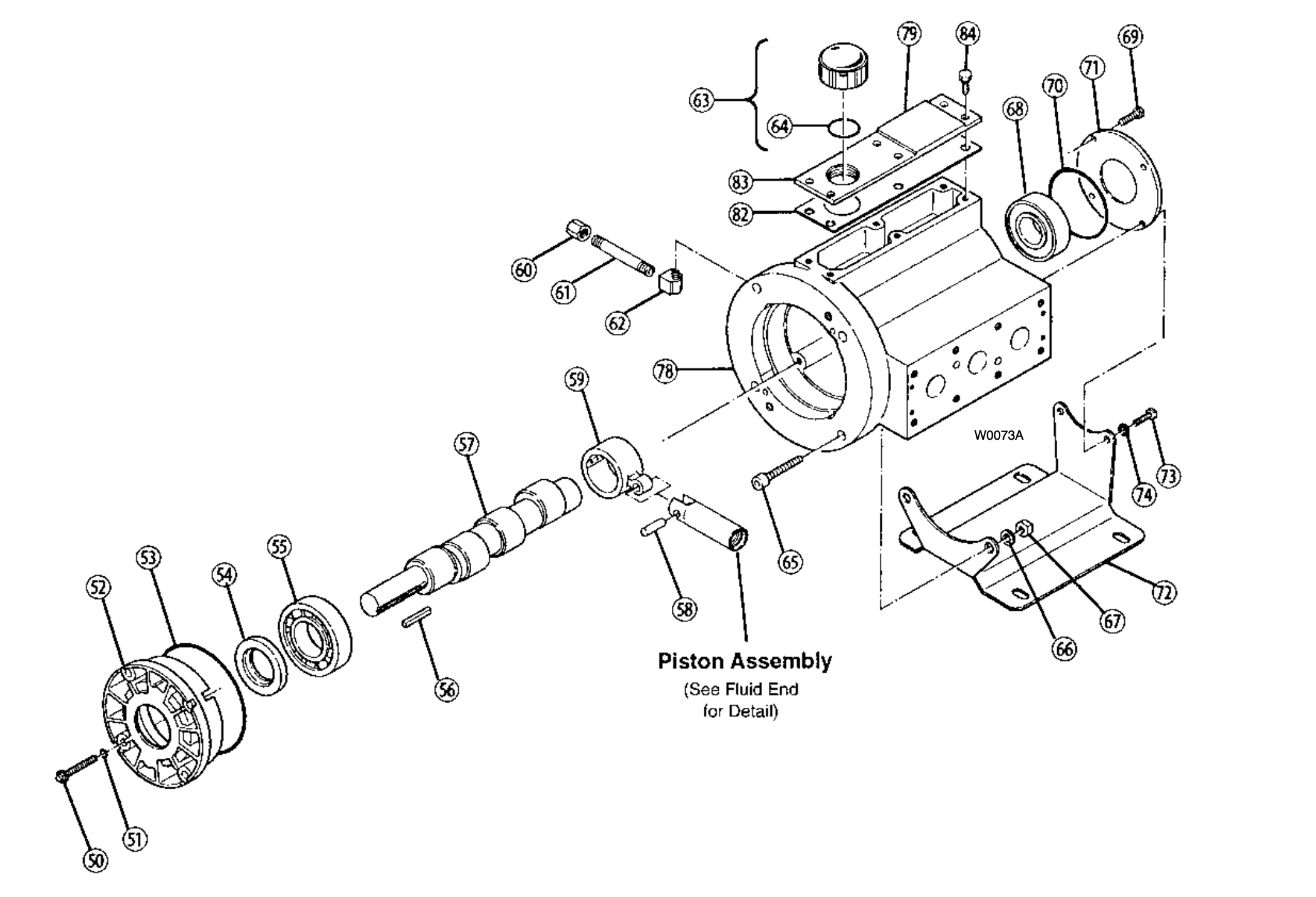

Click here to see: Instruction_Service_Manual

Click here to see: G04-Datasheet

Contact us by sending a message to:

AT Fluids at Applicazioni Tecniche Srl, Via Piaggio c/o Parco Paglia - Lotto B2, 66100 Chieti CH

Telephone : +39 0871 55 10 20

Whatsapp : +39 340 193 4855